Dryland Corn Yield Responses to Tillage Systems and Product Selection in Compacted Soils

April 21, 2025

TRIAL OBJECTIVE

- Successful corn production in dryland, otherwise known as low-rainfall environments, requires implementing the correct agronomic practices to help optimize crop performance and to help potential profitability.

- Soil compaction is a major challenge in corn production as it negatively impacts root development, water infiltration, and overall crop productivity.

- Different tillage systems influence soil structure, moisture retention, and compaction levels, potentially affecting corn product performance in low-rainfall conditions.

- Understanding how corn products respond to various tillage systems and production environments can help growers make informed management decisions to maximize yield potential.

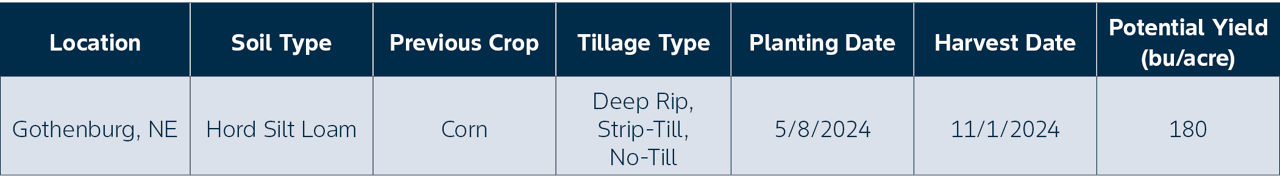

RESEARCH SITE DETAILS

- The dryland trial was established as a randomized complete block design with three replications, evaluating two treatment factors.

- Tillage system: deep rip, strip-till, and no-till

- Corn products: tall-105, tall-110, and short-112

- The three tillage systems evaluated were deep ripping, a deep tillage system; strip-till, a conservation tillage system; and no-till, where corn was planted directly into crop residue without prior tillage.

- Deep ripping consisted of using an in-line ripper set on 30-inch spacing and ripping occurred centered between the old corn rows in November 2023. The tillage depth was about 13 inches (Figure 1).

- Strip-till consisted of using an Orthmann® 1rRIPr strip tiller with a shank set at about 8 inches deep with the strips splitting the old 30-inch corn rows in November 2023 (Figure 1).

- The corn products evaluated were two tall corn products of 105 and 110 relative maturity (tall-105, tall-110), and one short-stature corn product of 112 relative maturity (short-112).

- Tall-105 was DEKALB® DKC105-33RIB Brand Blend with SmartStax® PRO Technology.

- Tall-110 was DEKALB® DKC110-10RIB Brand Blend with SmartStax® Technology.

- Short-112 was Preceon™ PR112-20RIB Brand Blend with VT Double PRO® technology.*

- A full 25 acres was utilized for the trial with each tillage strip measuring 60 feet wide by at least 2,000 feet long.

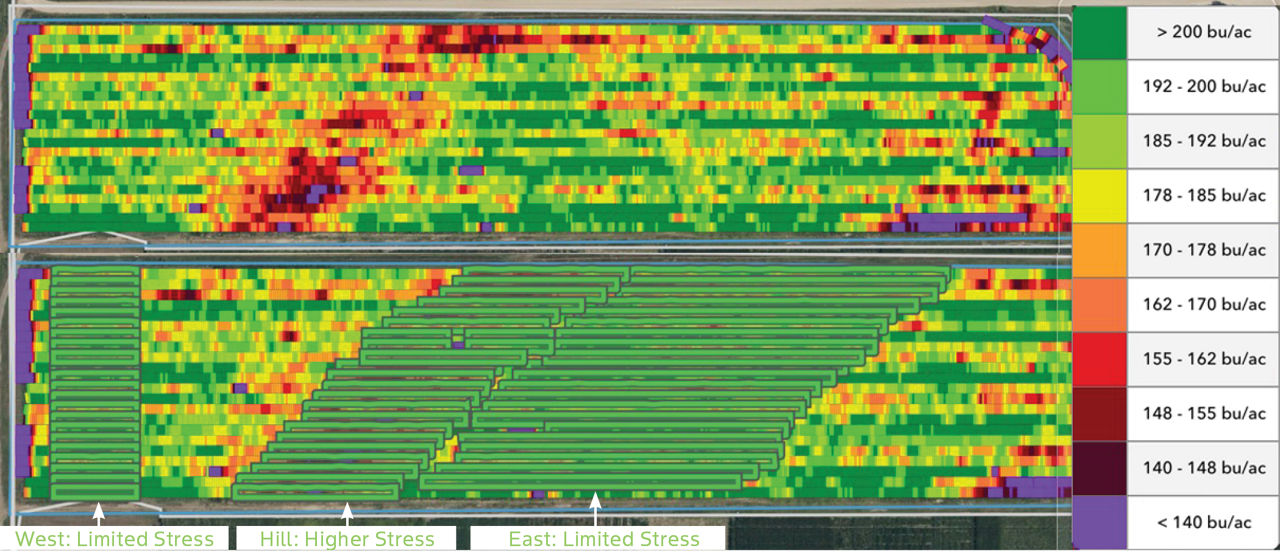

- The area was selected because of the shallow compaction identified in corn in 2023, during which large portions of the field yielded less than 40 bu/acre (Figure 2).

- The entire trial was planted on 5/8/2024 at 24,000 seeds/acre with an 8-row high speed planter at an average speed of seven miles/hour. Pictures of tillage treatments and residue levels were recorded before and after planting (Figure 3).

- Weeds were controlled uniformly in the trial.

- Nitrogen (N) fertilizer was applied at 140 lb N/acre as liquid 28-0-0, and was applied uniformly using 360 Y-DROP® fertilizer tube attachments on 6/18/2024 in the trial.

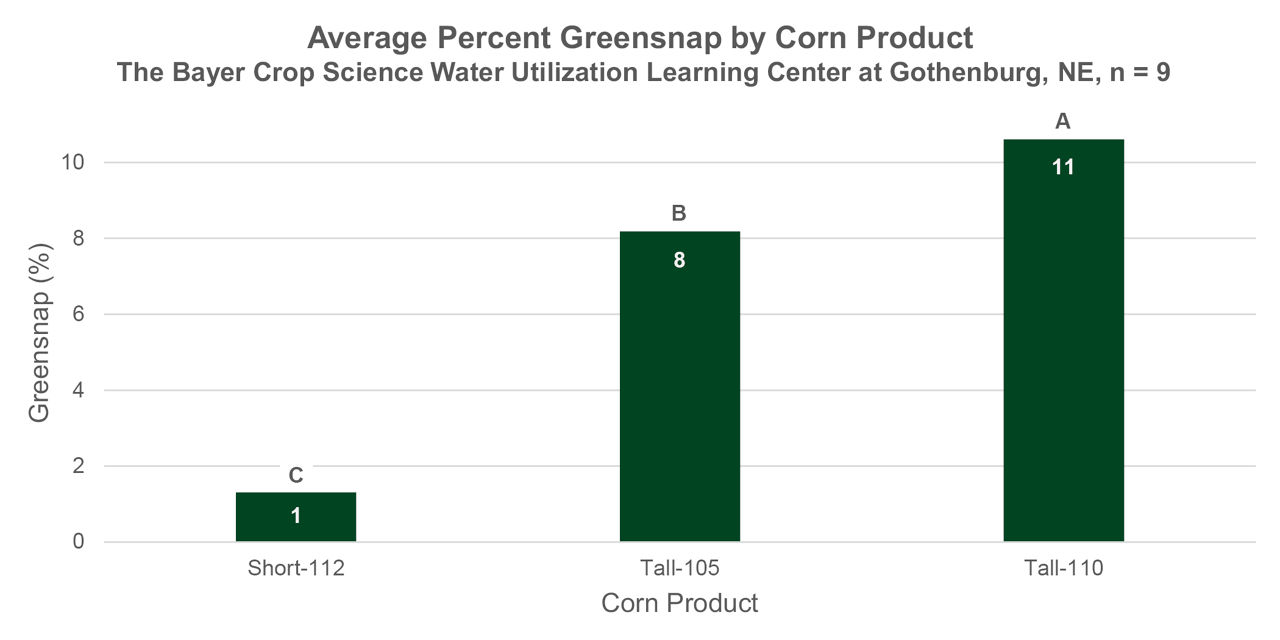

- Harvest stand count, stalk lodging, and greensnap data were collected just before harvest.

- Plots were combine-harvested with total plot weight, test weight, and percent moisture content being collected.

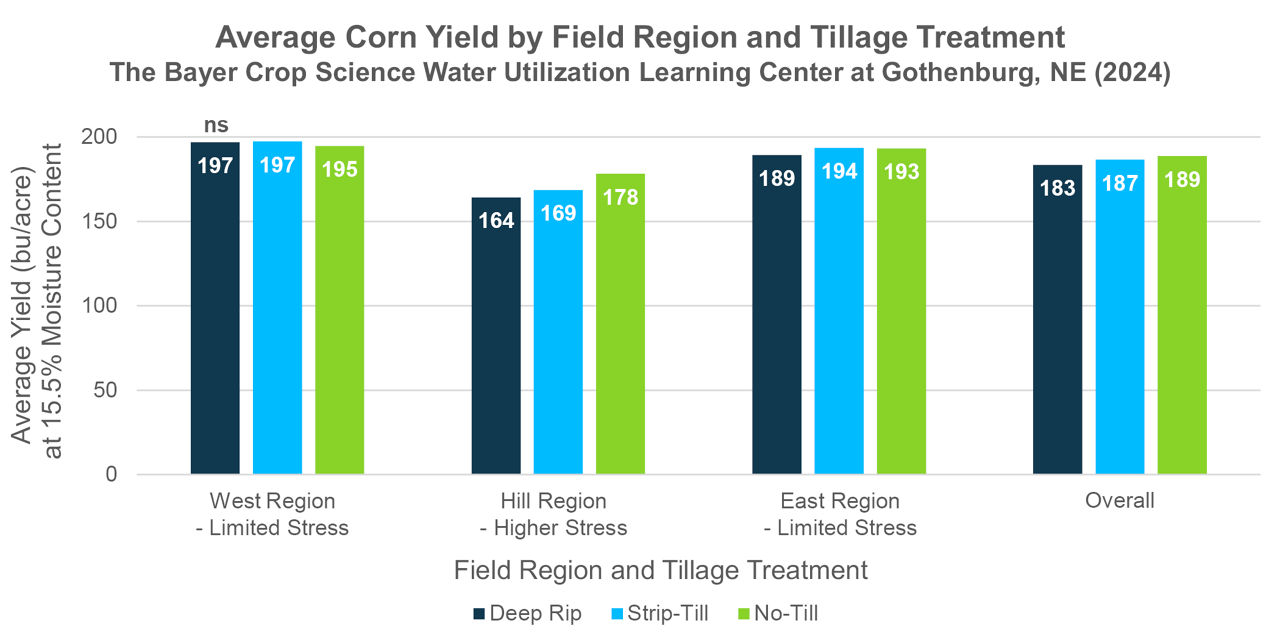

- The grain yield was corrected to a standard moisture content of 15.5%. Yield was calculated using field regions separated into higher-stress and lower-stress yield environments (Figure 4). The appearance of the plants in the high stress field region indicated that they experienced late season moisture stress.

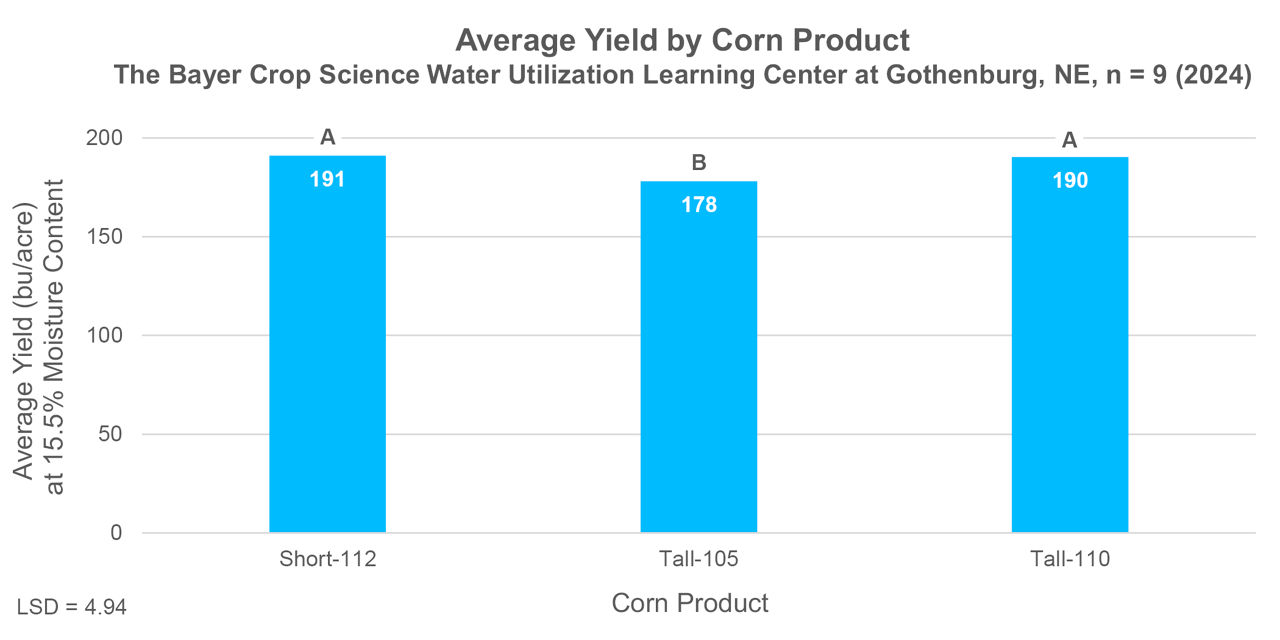

- Statistical analyses were performed on the data using Fisher’s LSD tests (Figures 5 and 6) and a Tukey’s test (Figure 7).

UNDERSTANDING THE RESULTS

- No significant differences in average yield were observed between the tillage systems in each field region or overall.

- In the high stress Hill field region, the no-till treatment produced an average yield 9 bu/acre higher than the strip-till treatment and an average 14 bu/acre higher than the deep rip treatment. These were the largest differences in average yield observed in the study.

- Despite the lack of significant differences in average yield, the trend suggests that reduced soil disturbance may contribute to improved moisture retention and overall crop performance under higher stress, moisture-limited conditions.

- Short-112 and tall-110 produced the highest overall yields, both significantly outperforming tall-105.

- Yield response showed a clear trend related to corn maturity, where corn products with longer relative maturity achieved higher average yields.

- A storm with wind and hail occurred on July 6, 2024, which caused greensnap in the field.

- Short-112 exhibited the strongest tolerance to greensnap, with a significantly lower average incidence than either tall corn product.

- In this trial, the superior performance of the short-stature product suggests greater tolerance to greensnap compared to traditional tall corn products.

KEY LEARNINGS

- Soil compaction was not measured in this trial, but in the first year in which this trial was conducted the yield results from tillage practices meant to alleviate the shallow compaction did not show an advantage. This could have been due to the natural freeze-thaw cycle that can help reduce shallow-depth soil compaction.

- While no significant yield differences were observed among tillage systems, the no-till treatment had the highest yield advantage in the in the high stress field region, suggesting that no-till management can be a viable strategy for conserving soil moisture and maintaining productivity in dryland environments.

- Short-112 and tall-110 produced higher average yields than tall-105, reinforcing the importance of selecting products with maturity ratings suited to local growing conditions.

- Short-112 exhibited the lowest average percent greensnap incidence in a natural greensnap scenario that occurred at about the V16 growth stage, demonstrating significantly more tolerance to greensnap than the taller corn products.

- Soil compaction remains a challenge, affecting root development and water infiltration. Deep tillage did not significantly improve average yields in this study, and growers should assess soil conditions and consider conservation tillage practices (e.g., strip-till, no-till) to balance soil structure and moisture conservation.

- This trial will be assessed again in 2025 to evaluate potential differences in soil compaction in the second year, as these tillage practices influence soil conditions for several years.

*The Preceon™ Smart Corn System, including short stature corn products developed through traditional breeding, is commercially available for planting in the 2025 growing season via the Ground Breakers® program.

1221_530650

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.