Herbicide Mixing Order

April 17, 2025

Herbicide efficacy can be improved by using the proper mixing order when multiple products are applied in a single application. Proper mixing order ensures products do not gel or form precipitates that could clog or even damage spray equipment, and prevents product antagonism from occurring.

Follow the specific pesticide label requirements when using any pesticide. However, if the label does not specify the mixing order, the following is recommended.

Products should only be added to a clean tank. If the intended tank is not already clean, before adding products, clean the tank by filling 10 to 50% of its volume with clean water and add a cleaning agent to the correct dilution rate according to its label. Agitate the solution to ensure proper circulation of cleaning agent throughout the system, including the boom and nozzles. When approximately 5% of the solution remains, completely refill the tank to 100% full and repeat the entire process. At this time, inspect the sprayer parts, such as nozzles or screens, and clean and replace as required to ensure uniform application.

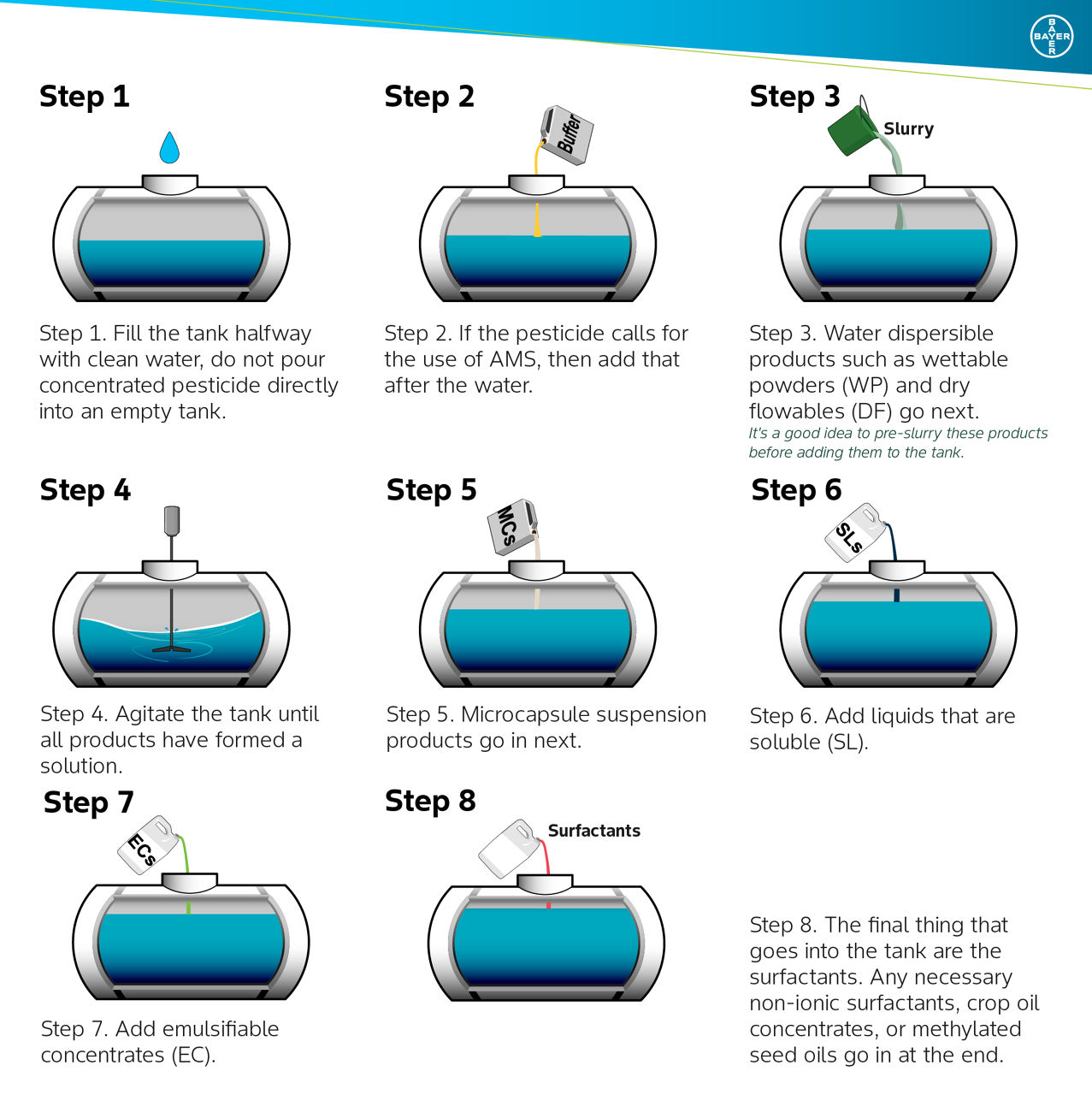

Step 1. Use clean water or another carrier to fill a clean tank to 50 to 75% full. If fertilizer is used as the carrier, a higher initial volume of 75% is required. If an inductor is used, rinse it thoroughly after each component is added. Add any compatibility agent and/or defoamer.

Step 2. Add ammonium sulfate (AMS). AMS requires constant agitation. This product should be completely dissolved before the addition of other chemicals. AMS that is not properly dissolved can clog spray equipment and result in compatibility issues with various water sources. However, a product that includes AMS and a premixed surfactant will typically be added last.

Step 3. Add water dispersible products such as wettable powders (WP), dry flowables (DF), and granular (G) products. Wettable powders should first be made into a slurry by mixing them with water at the proper ratio, then should be slowly added to the spray tank.

Step 4. Constantly agitate the contents to ensure all products stay in solution.

Step 5. Add microcapsule suspension (ME) products such as products labeled suspension concentrate (SC), aqueous suspension (AS), or capsule suspension (CS). Ensure the proper surfactants are used with suspension-formulated herbicides as per label directions. Encapsulated formulations must remain in solution, so continue with agitation.

Step 6. Add liquids that are soluble (SL). These are liquid herbicides or additives that are water-based.

Step 7. Add emulsifiable concentrates (EC). Adding these oil-based liquids (EC) before soluble liquids can cause compatibility issues with other additives and potentially reduce efficacy.

Step 8. Add surfactants such as a non-ionic surfactant (NIS), crop oil concentrate (COC), or methylated seed oil (MSO). These should be added last after everything has been properly mixed into solution. Add remaining water and continue agitation throughout application.

Always consult the product label when unsure of proper mixing procedure or order.

Source:

Galvin, L. 2024. Herbicide mixing order for effective pesticide application. Oklahoma State University. https://extension.okstate.edu/fact-sheets/herbicide-mixing-order.html

1026_512450

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.