Storing Grain Compromised by Mold and Mycotoxins

November 5, 2025

- Ear mold growth and mycotoxin production can continue in stored grain if moisture and temperature are not lowered.

- Visual observations of ear molds do not indicate mycotoxin levels.

- Guidance for mycotoxin levels is more restrictive for some food and feed end uses.

- Combine adjustments during harvest and aeration during storage are options for managing limited mycotoxin contamination in grain.

Mycotoxin Presence Versus Fungal Infection

Mycotoxins are chemicals produced by some ear rot fungi: aflatoxin (Aspergillus ear rot), fumonisins (Fusarium ear rot), and deoxynivalenol (Gibberella ear rot). Unlike fungal organisms, mycotoxins are exceedingly stable; temperature extremes or chemical treatment do not reliably reduce their levels in kernels. Even healthy-looking kernels can be contaminated with mycotoxins when nearby kernels are diseased. Therefore, do not rely on ear rot levels to indicate mycotoxin levels.

Scouting and Segregating Moldy Corn

The first line of defense against further grain degradation is field segregation or separate storage of grain with high mycotoxin levels. Scout fields for Gibberella, Aspergillus, and Fusarium ear rots prior to harvest. Fields in which 10% or more of the ears are infected with these rots could have concerning levels of mycotoxin.1

Fungal disease complexities and similarities are another reason to scout and sample grain. For instance, Fusarium verticillioides produces symptoms indistinguishable from Fusarium proliferatum and Fusarium subglutanins. However, only F. verticillioides and F. proliferatum produce fumonisin toxins.2

Combine Adjustments for Disease-Compromised Ears

Aflatoxin and fumonisin contamination tend to be concentrated in light, damaged kernels. To reduce these contaminated kernels and lighter materials in loads –

- Harvest fields affected by Aspergillus and Fusarium ear rots with the lowest possible rotor or cylinder speed. This precaution should shell grain off ears while not exceeding losses of 1 percent.3

- Going in a lower, slower gear is recommended to reduce cracked, broken kernels.

- Allow adequate air flow to blow off chaff and lighter, damaged grain.

Contracted Grain and Point of Sale

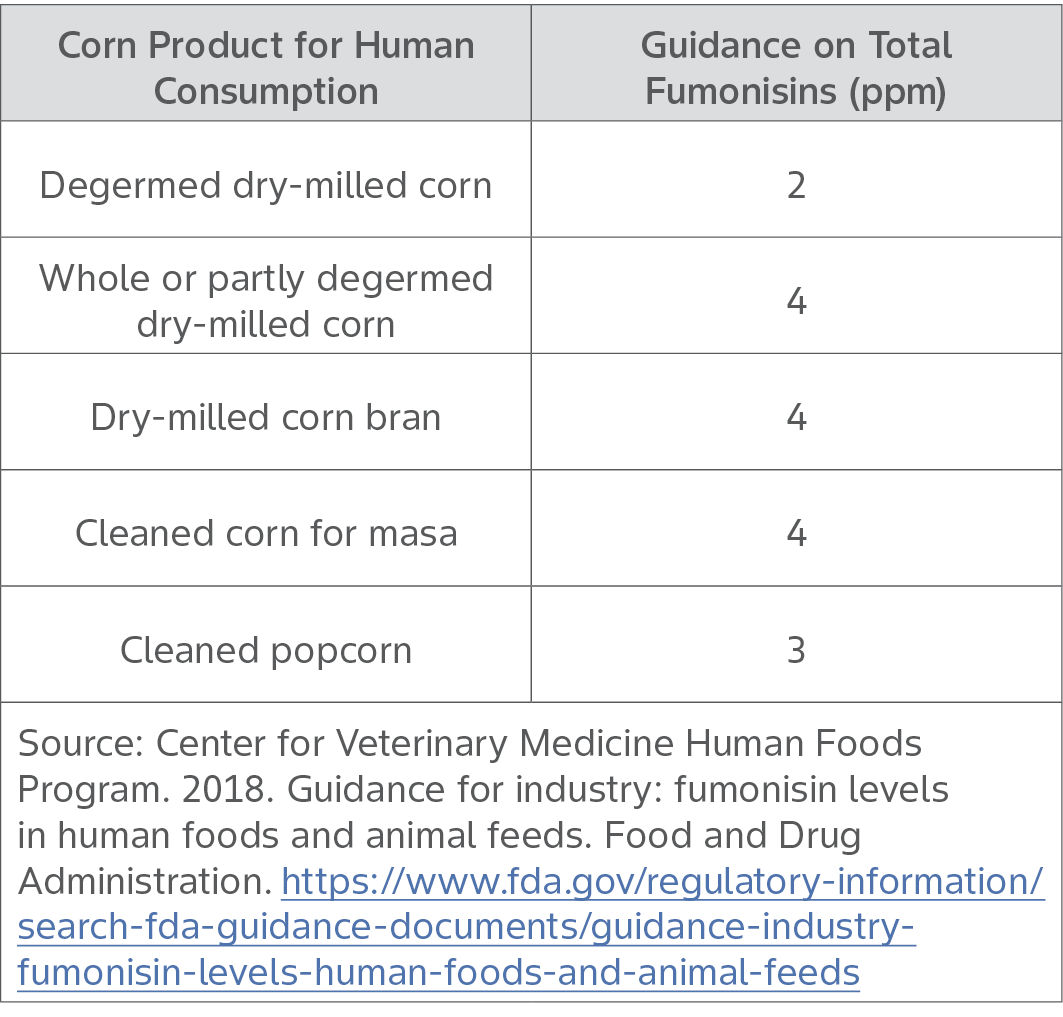

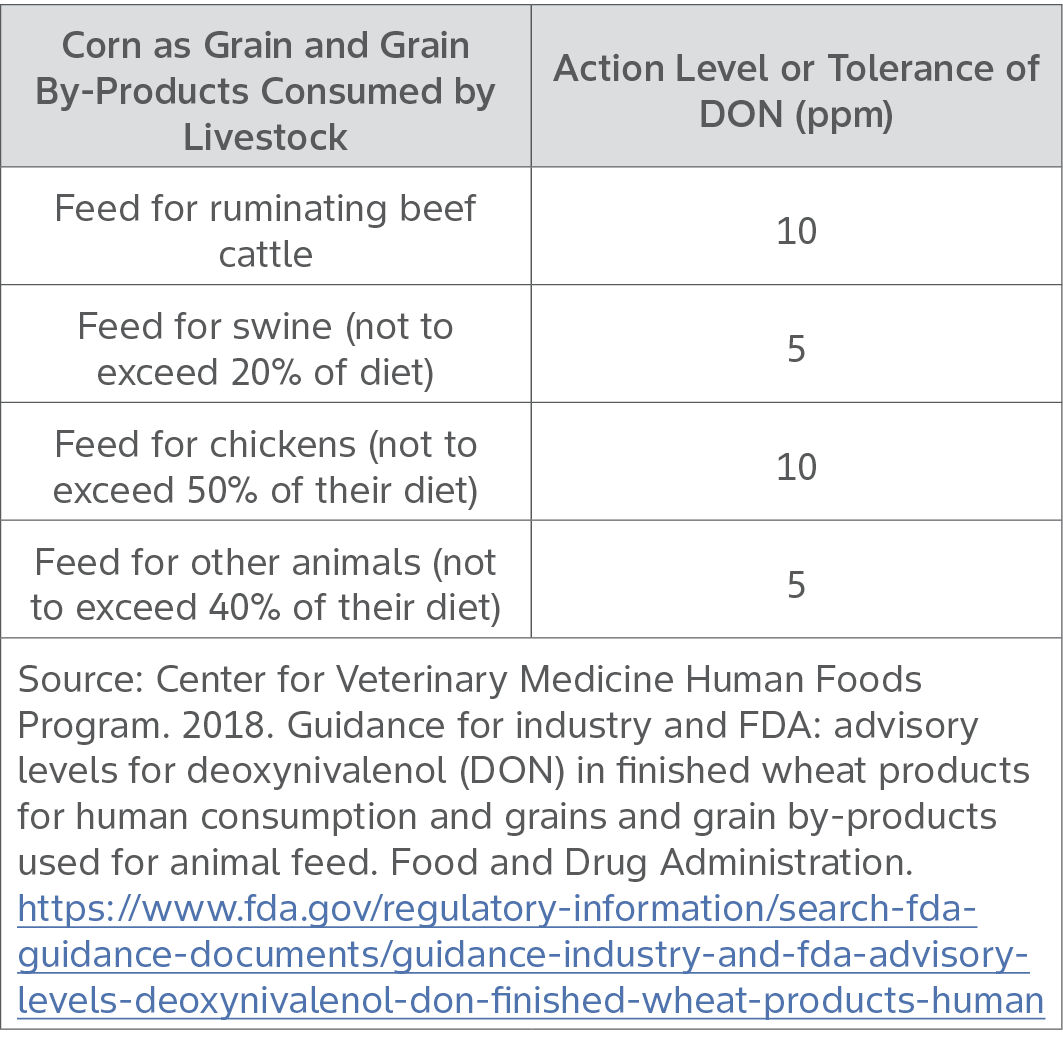

Tolerable mycotoxin concentrations are often pre-determined in a specialty contract. Where corn grain is being grown as food grade, pet food grade, or livestock feed, mycotoxin levels become important and will likely be tested at the point of sale (Tables 1, 2, and 3).1 In extreme cases, mycotoxin levels that exceed legal and advisory levels may cause the grain to be destroyed. More commonly, tested loads may have prices docked or be rejected for the original contracted purpose of producing food or feed. Corn exports are also subject to limits from importing countries, could have more restrictive requirements for mycotoxin levels.

Table 1. Fumonisin guidelines for food consumption in the United States.

Table 2. Aflatoxin guidelines for animal feed and human food consumption in the United States.

![Table shows aflatoxin tolerance guidelines by corn product for feed & food consumption.]](https://cs-assets.bayer.com/is/image/bayer/aflatoxin-guidelines-corn-products-animal-human-consumption)

Table 3. Deoxynivalenol (DON) or vomitoxin guidelines for feed in the United States.

Post Harvest Storage Management

Post harvest practices should keep ear mold fungi from breaking dormancy in kernels. Storage conditions can increase, but not decrease, mycotoxin levels in grain. Mycotoxin levels cannot be visually determined in a load of commercial grain, and contamination could be concentrated in kernels. A single kernel with a mycotoxin level of 400,000 ppb makes a 10-lb sample measure 26 ppb.4 Federal regulations prohibit blending mycotoxin-contaminated (level exceeds action level) edible grains with ‘clean’ grain.

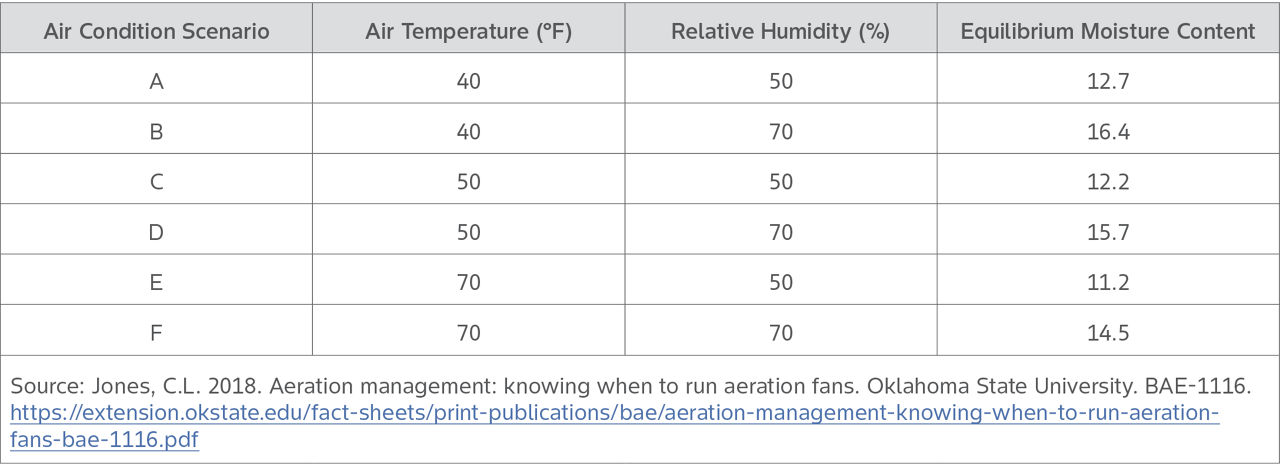

Cooling and drying grain compromised by molds and mycotoxins should begin immediately after harvest. Further mycotoxin production can be stopped by drying grain to 13% moisture.1 Aflatoxins can still accumulate in grains with greater than 16% moisture, and aeration should be run when possible to maintain or lower equilibrium moisture contents to 13% for long-term storage.

Aeration should be run in air condition scenarios such as A, C, and E from Table 4, below. However, other conditions may permit aflatoxin production regardless of aeration. For example, if the air temperature was 40 °F with a relative humidity of 70%, the equilibrium moisture content could increase above 16% and aflatoxin production becomes a greater risk. Recommendations for keeping moisture from condensing during periods of uneven heating can be found in our article Managing Stored Grain During Fluctuating Temperatures in the Late Fall and Winter.

Table 4. Equilibrium moisture contents for corn from three different temperatures and two different relative humidity levels.

Conditioning or cleaning grain to remove cracked kernels, fines, and lightweight material could reduce overall mycotoxin levels. Density separators sort healthier, heavier grain from less developed, damaged grain. In loads with severe mycotoxin contamination, cleaning grain may not improve the condition enough to avoid discounts at the point of sale.1

Sources

1Smith, D., Allen, T., Chilvers, M., Faske, T., Isakeit, T., Mueller, D., Price, T. Tenuta, A., and Wise, K. 2025. Corn mycotoxin FAQs. Crop Protection Network. CPN-2002. https://doi.org/10.31274/cpn-20190620-005

2Woloshuk, C. and Wise, K. 2014. Diseases of corn Fusarium Ear Rot. Purdue University. BP-86-W. https://extension.purdue.edu/extmedia/bp/bp-86-w.pdf

3Faske, T., Allen, T., Chilvers, M., Isakeit, T., Mueller, D., Price, T., Smith, D., Tenuta, A., and Wise, K. 2025. Storing mycotoxin-affected corn grain. Crop Protection Network. CPN-2004. https://doi.org/10.31274/cpn-20190620-007

4Isakeit, T. 2013. Management of aflatoxin in corn [Presentation]. Texas A&M AgriLife Extension and Research. https://doi.org/10.1094/GROW-COR-10-13-055

Web sources verified 10/31/2025. 1211_683100.

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.