Corn Yield Analysis of Simulated Planting Errors: Missed Rows & Corn Compensation – South 2025

January 13, 2026

TRIAL OBJECTIVE

- The ability of corn to compensate for missing rows – often in the case of equipment malfunctions – is a primary question for farmers.

- A secondary question is: what contribution do secondary ears make to yield potential in both solid and skipped row plantings?

- During the early 2025 planting season, several growers experienced planting scenarios with missed rows, and the Bayer Crop Science Learning Center at Scott, MS simulated the effect in experiments and measured corn grain response.

- These data can give guidance regarding field replants where missing row errors occur.

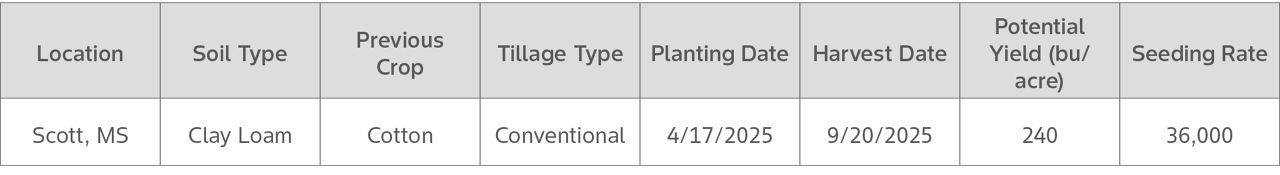

RESEARCH SITE DETAILS

Table 1. DEKALB® brand corn products, traits, and maturities grown.

- All field work, tillage, and herbicides were per local standards.

- The trial used non-replicated strip plots.

- 12-row plots were set up to simulate missing row configurations because of equipment malfunctions. The following treatments were included:

- No Rows Missing; the untreated check (UTC).

- Row 2 Off

- 1 row missing of 12

- Rows 2,4 Off

- 2 rows of 12 missing; separated by 1 planted row

- Rows 5,6 Off

- 2 rows of 12 missing side by side –This would simulate and end row planter malfunction where 2 rows were skipped side by side.

- Rows 2,4,6 Off

- 3 rows of 12 missing; separated by planted rows

- Rows 2,4,6,8 Off

- 4 rows of 12 missing; separated by planted rows

- Rows 2,4,6,8,10 Off

- 5 rows of 12 missing; separated by planted rows; this configuration also demonstrated “skip row” corn planting.

- Plot Size – 12 row plots, 145 feet long; or 0.15 acre/plot

- Ear Sampling – 10-row feet of each plot area were sampled from each plot area to estimate ear size and secondary ear yield accumulations. Samples were taken from:

- Solid areas of each plot – no skip on either side of the row

- Rows with skip on one side

- Rows with skips on both sides

- Secondary ear weight – a total of 4 secondary ears sampled across the study.

- A total of 679 ears were sampled from the plots. This was primarily to estimate the secondary ear contribution to yield potential.

- From this data, 675 primary ears were collected; note a total of 4 secondary ears with a grain contribution were collected from the same plants.

- Ear Sampling – 10-row feet of each plot area were sampled from each plot area to estimate ear size and secondary ear yield accumulations. Samples were taken from:

UNDERSTANDING THE RESULTS

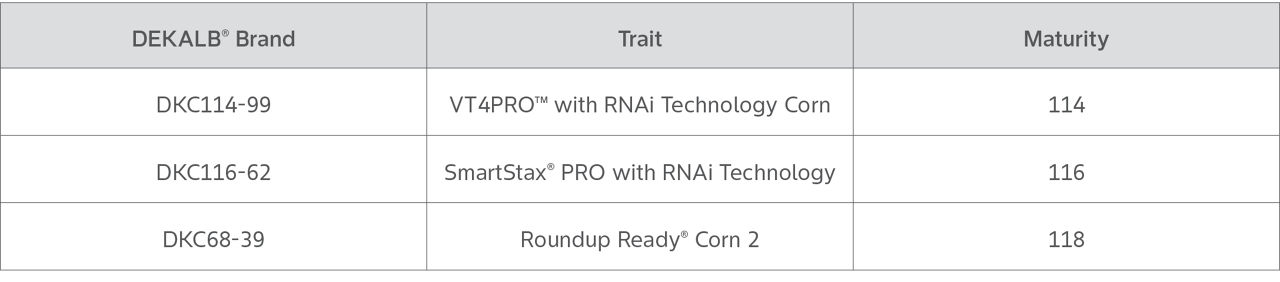

Table 2. Averaged across three corn products, ear size response and percent increase over ear size in solid row configuration.

- Almost all plants had secondary ears at pollination, and the initial hypothesis was secondary ears would contribute to yield compensation (Figure 1). Of the 679 ears sampled only 4 were secondary ears making a grain contribution to yield and those ears were quite small – approximately 50% of the primary ear weight (Table 2). Results from Scott, MS during 2025 do not support secondary ears as viable yield contributors to compensate for planting errors.

- Some compensation did occur across the plots. This compensation was mostly due to increases in primary ear size. Ears harvested from rows with a skip on one side were reported to be 3.4% larger than ears from solid planted rows while ears from rows with a skip on both sides were reported 15.4% heavier than ears from the solid planted areas (Table 2).

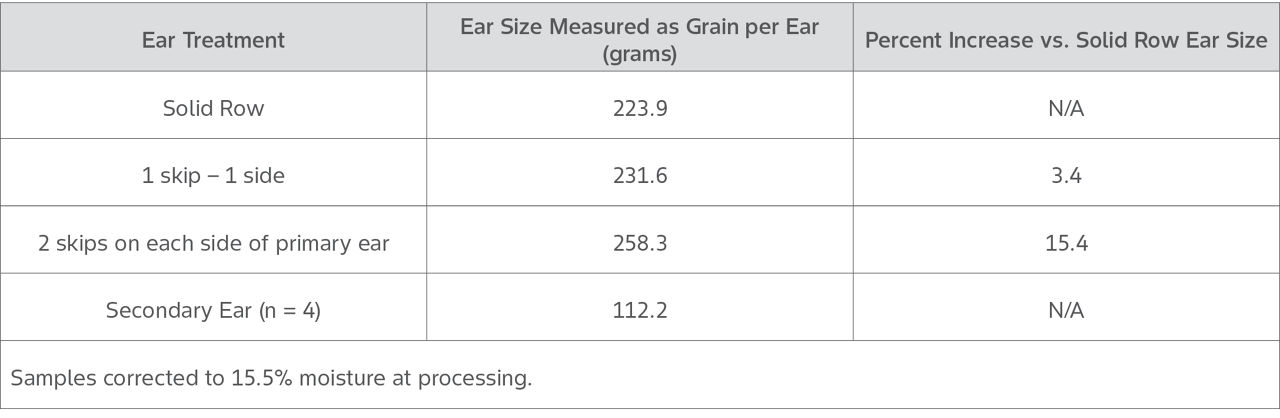

Table 3. Response of corn to missing rows compared to solid-row configuration.*

- When considering the combine-harvested yields, compensation was observed. In plots where the Treatment was Row 2 Off, corn was 8.3% unplanted (Figure 2). However, this treatment yielded 94.1% of the solid-planted configuration and indicated about 2.5% of the yield from a single-missing row configuration was compensated for by surrounding rows (Table 3).

- Where 2 adjacent rows were skipped (Figure 3) 16.7% of the plot was unplanted but yield was 86.4% of the solid planted areas indicating about 3.1% of the missing yield was compensated for in the planted rows (Table 3).

- Where a single planted row was between two unplanted rows, 16.7% of the area was unplanted (Figure 4). However, the plot yield was 90.1% of the solid planted areas indicating approximately 6.8% compensation for the missing rows (Table 3).

- Compensation in missing row treatments proceeded roughly linearly from the Treatment Rows 2,4 Off with more area missing, the lower yield potential. Similar levels of compensation occurred in Treatments with every other row turned off up to Row 10.

KEY LEARNINGS

- Data from this study shows little, if any, compensation occurs in corn fields from expression of secondary ears where rows are unplanted on either side or any of the tested configurations.

- Varying levels of compensation do occur via increases in primary ear size when planting errors introduce skipped rows into fields.

- Corn plants could not fully compensate for missing rows, but the entire yield potential is not lost.

- This data should be used along with other factors associated with replanting including replanting cost, weather delays, planting date yield penalties, and other variables associated with the process.

- Please contact your local DEKALB® brand representative for more information.

1214_698750

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.