Cotton Trials to Evaluate Agronomic Interactions in Boll Locule Development

June 20, 2023

To compare yearly research data, click on a tab.

TRIAL OBJECTIVE

Part I – Cotton Row Configuration

- Cotton planted on wider rows (up to 80-inches apart) has been discussed around the cotton industry for several years.

- The potential advantages of wide row and skip row configurations are equipment standardization across crops, reduced excessive growth via reduced plant to plant competition, and lower input costs with lower seeding costs and banding of inputs.

- Ongoing research is important for variety selection, appropriate management, and yield potential in wider row cotton plantings.

- This study was initiated at the Bayer Learning Center at Scott, MS to evaluate the potential of wide row cotton plantings in the production system.

Part II – Investigations into the Five Locule Boll

- A long-standing cotton mystery has been the five locule boll, which occurs at some level in most cotton fields.

- Questions regarding five locule bolls versus four locule bolls include:

- Do five locule bolls weigh more than four locule bolls?

- Do five locule bolls produce more seed and/or lint per boll than four locule bolls?

- What is the relative fiber quality of five versus four locule bolls?

- What contribution do five locule bolls make to lint yield?

- What factors can potentially influence the development of five locule bolls?

- This study was an offshoot of the row configuration work.

- This work helps explain the agronomic impacts on boll locule number and some of the compensatory mechanisms that cotton shows at reduced populations.

- Some variety effects were also evaluated and are included in this analysis.

Part II B – Agronomic Interactions

- Inherent to this work, several agronomic factors including seeding rates, planting density down the row, variety, and row configuration had an influence on five locule development.

RESEARCH SITE DETAILS

| Location | Scott, MS |

| Soil Type | Silty/Sandy, Clay Loam |

| Previous Crop |

Corn |

| Tillage Type |

Conventional |

| Planting Date | 05/1/22 |

| Harvest Date | 10/10/22 |

| Potential Yield (bu/acre) |

1200 |

| Seeding Rate (seeds/acre) |

See Below |

- Plots were approximately one acre each.

- Weed and insect controls were applied at local standard rates and timings.

- Nitrogen at a rate of 90 lb/acre was applied as 28-0-0-5 (N-P-K-S).

- Row configurations planted:

- 38-inch Solid Seeded

- 38-inch Skip Row (2:1) 2 rows planted, 1 row skipped

- 76-inch centers with (1:1) 38-inch Wide Row, effectively 1:1 skip row.

(This is planted as a proxy for 60-inch rows which is how wide row cotton is being planted. The Learning Center does not have 30-inch equipment and cannot effectively plant 60-inch rows due to drainage issues on 30-inch beds; therefore, 76-inch rows are used).

- Deltapine® brand cotton varieties planted

- DP 2012 B3XF (early maturity) – due to field space and adaptation, this product was not included in the 76-inch (1:1) planting configuration.

- DP 2020 B3XF (early to mid-maturity)

- DP 2127 B3XF (early to mid-maturity)

- DP 2038 B3XF (mid-maturity)

- DP 1646 B2XF (mid-maturity to full season)

- Seeding rates per land acre

- 20,000

- 30,000

- 40,000

- 50,000

- Mepiquat chloride 4.2% plant growth regulator (PGR) was applied at labeled rates to the row configuration treatments on dates relative to growth stage (9, 14, and 17 nodes):

- 38-inch Solid

- 6/14/2022 – 8 nodes - 12 fl oz/acre

- 7/3/2022 – 13 nodes - 12 fl oz/acre

- 7/12/2022 – 16 nodes - 16 fl oz/acre

- 76-inch Wide Row (1:1)

- 6/14/2022 – 8 nodes - 8 fl oz/acre

- 7/3/2022 – 13 nodes - 10 fl oz/acre

- 7/12/2022 – 16 nodes - 12 fl oz/acre

- 38-inch Skip Row (2:1)

- 6/14/2022 – 8 nodes - 8 fl oz/acre

- 7/3/2022 – 13 nodes - 10 fl oz/acre

- 7/12/2022 – 16 nodes - 12 fl oz/acre

- 38-inch Solid

- The plots were intensively managed by row configuration. Each production system was managed independently for water, mepiquat chloride, and defoliation to help maximize lint yield potential in the Delta environment.

- The 2022 early growing season at Scott, MS was average with adequate rainfall events and relatively light insect infestations. This likely gave the row configurations an “equal” footing to begin fruit accumulation and establish yield potential.

- Plots were machine harvested for lint yield after defoliation. Subsamples were mapped for fruiting profile estimations.

Data collected

- Plots were monitored for growth and development throughout the season.

- Box Mapping – Plots were positionally mapped using the Boll-O-Meter (Figure 2) to evaluate fruiting profile and boll parameters such as seed weight, seed number, and fiber quality:

- Fruiting profile of the variety x seeding rate x row configuration combinations.

- Sample ginning – All box mapping samples were bulked, ginned, and sent through High Volume Instrument (HVI) testing for both turnout and fiber quality evaluations.

- Delinting – Mapping samples were segregated by treatment combination, locule number, and bulked together by locule cohort before ginning. After ginning, seeds were weighed fuzzy (in bulk), delinted, counted, and weighed post delinting (black) for reporting. This was primarily completed to evaluate the influence of locule number on seed and lint weight and corresponding influences on lint yield and fiber quality.

UNDERSTANDING THE RESULTS

Part I-Row Configuration Evaluations and Observations

- Row configuration

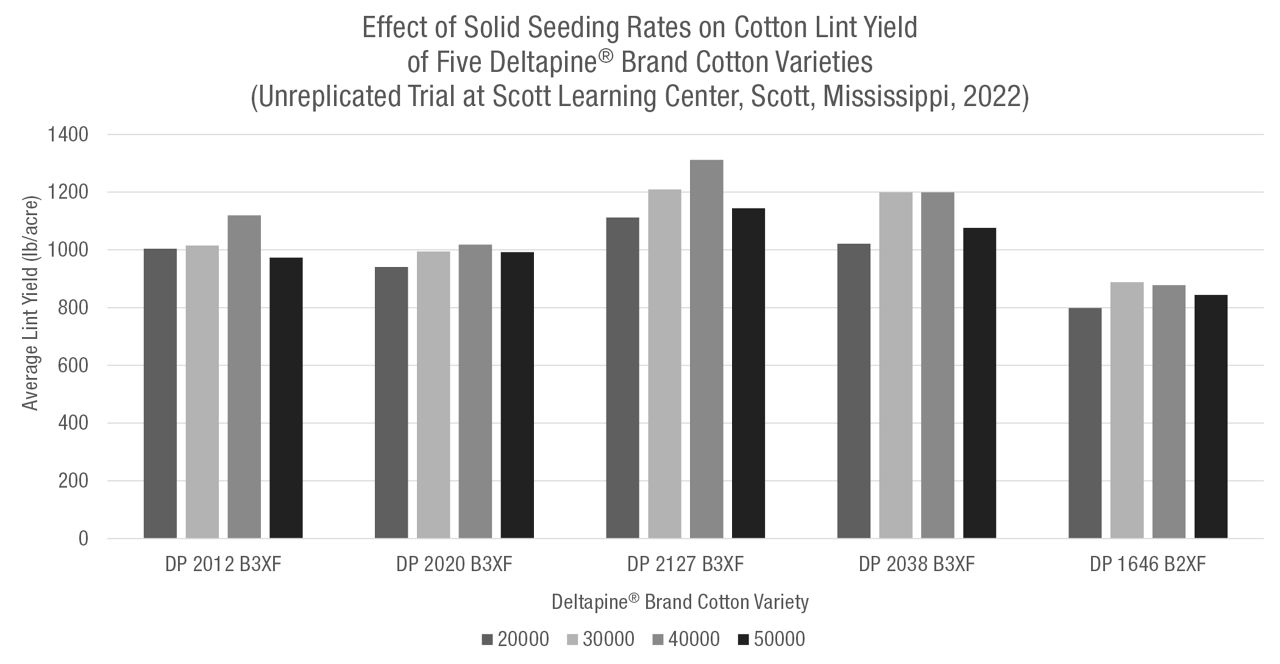

- The 38-inch solid configuration produced an average yield of 1037 lb lint/acre (Figure 3).

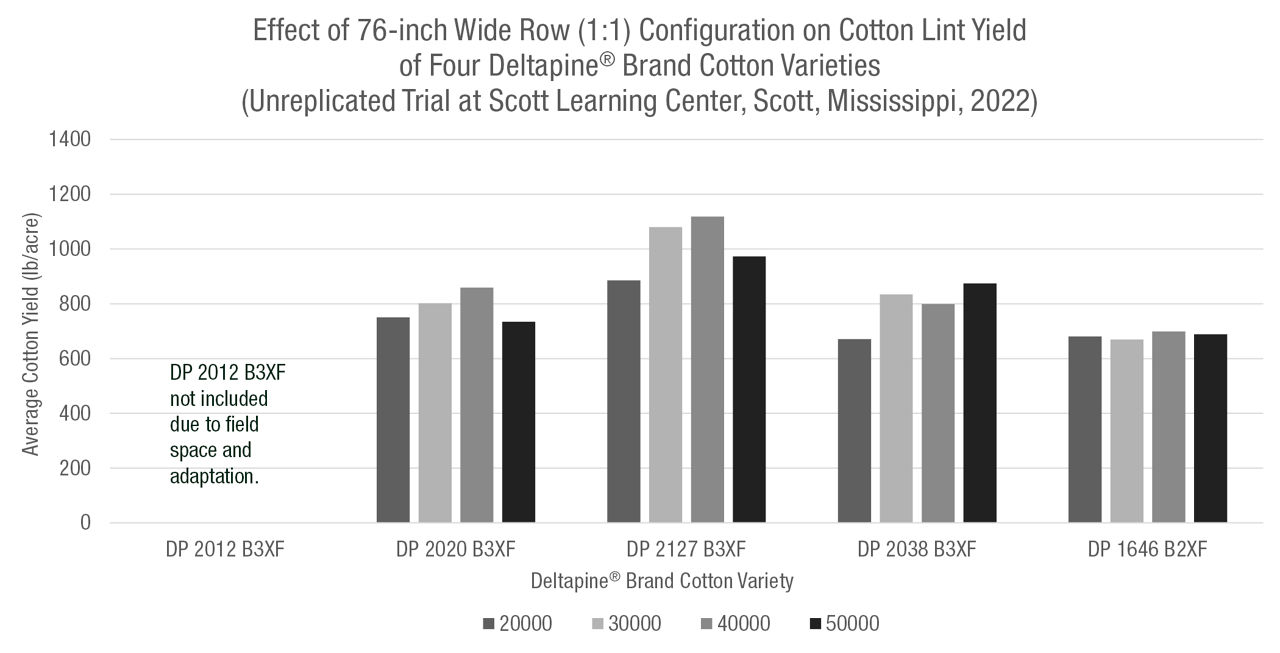

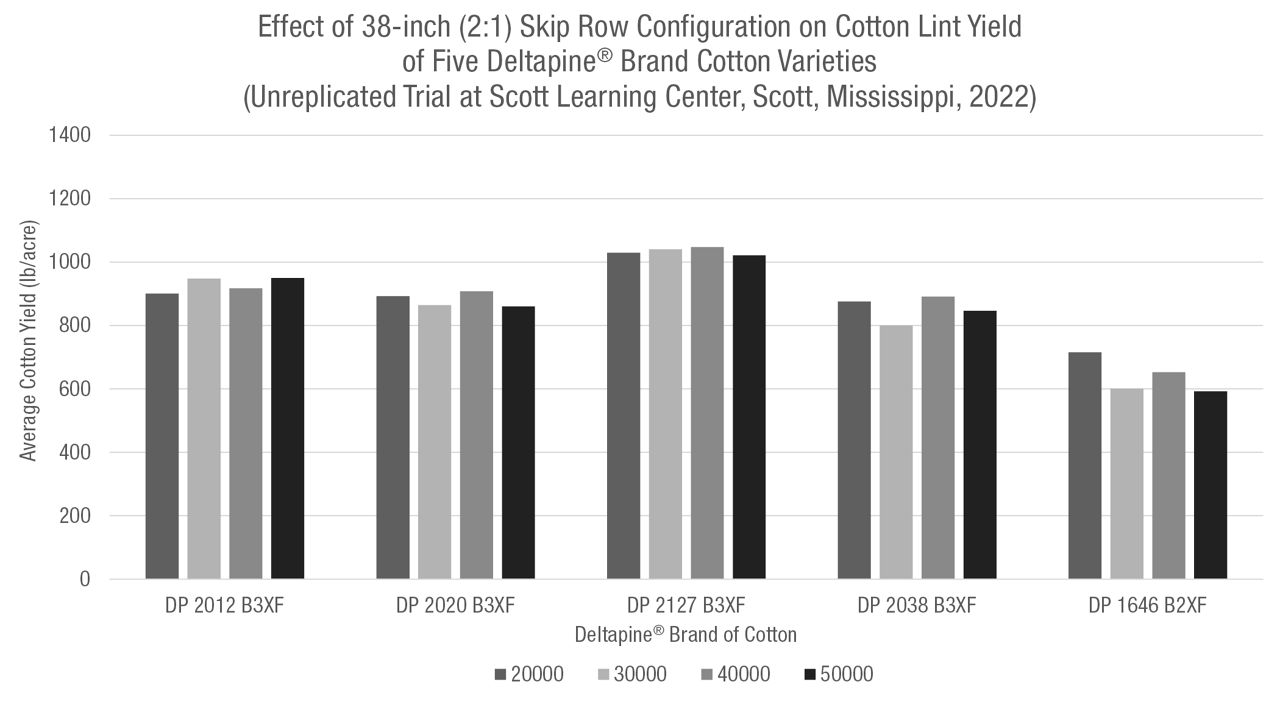

- The 76-inch (1:1) wide row (Figure 4) and 38-inch (2:1) skip row (Figure 5) treatments showed somewhat reduced average lint yields of 820 to 868 lb lint/acre, respectively.

- Comments about results:

- While the solid plantings were higher yielding, several of the wider/skip row treatment combinations showed average yields of 1,000 to 1,100 plus lb lint/acre. Growers should acknowledge this limitation before pursuing either alternative row spacing as a production practice.

- Variety selection should be carefully evaluated before selecting a variety for wide row production.

- An important note – these differences are likely to narrow as row configuration moves closer to 60-inches but may also remain. Further investigation is warranted.

- Seeding Rates

- Seeding rate is a factor many growers use to moderate vegetative development and supplement or improve the effectiveness of PGR applications.

- Seeding rate appears to be optimized in this study between 30,000 to 40,000 seeds/acre. This agrees with commercial practice.

- It appears that reducing the seeding rate in solid row plantings does not greatly decrease yield potential.

- Yields appeared to be slightly higher in the 76-inch wide rows (1:1) at the lowest seeding rates but at levels of 200 to 300 lb lint/acre lower than in the solid plantings (Figure 4). This points out one fundamental limitation of the wide row planting.

- Growers should carefully evaluate seeding rate decisions and variety response when a change is being considered. However, cotton yield potential appears to be mostly maintained even at relatively low seeding rates.

Part II - Investigations into the Five Locule Boll

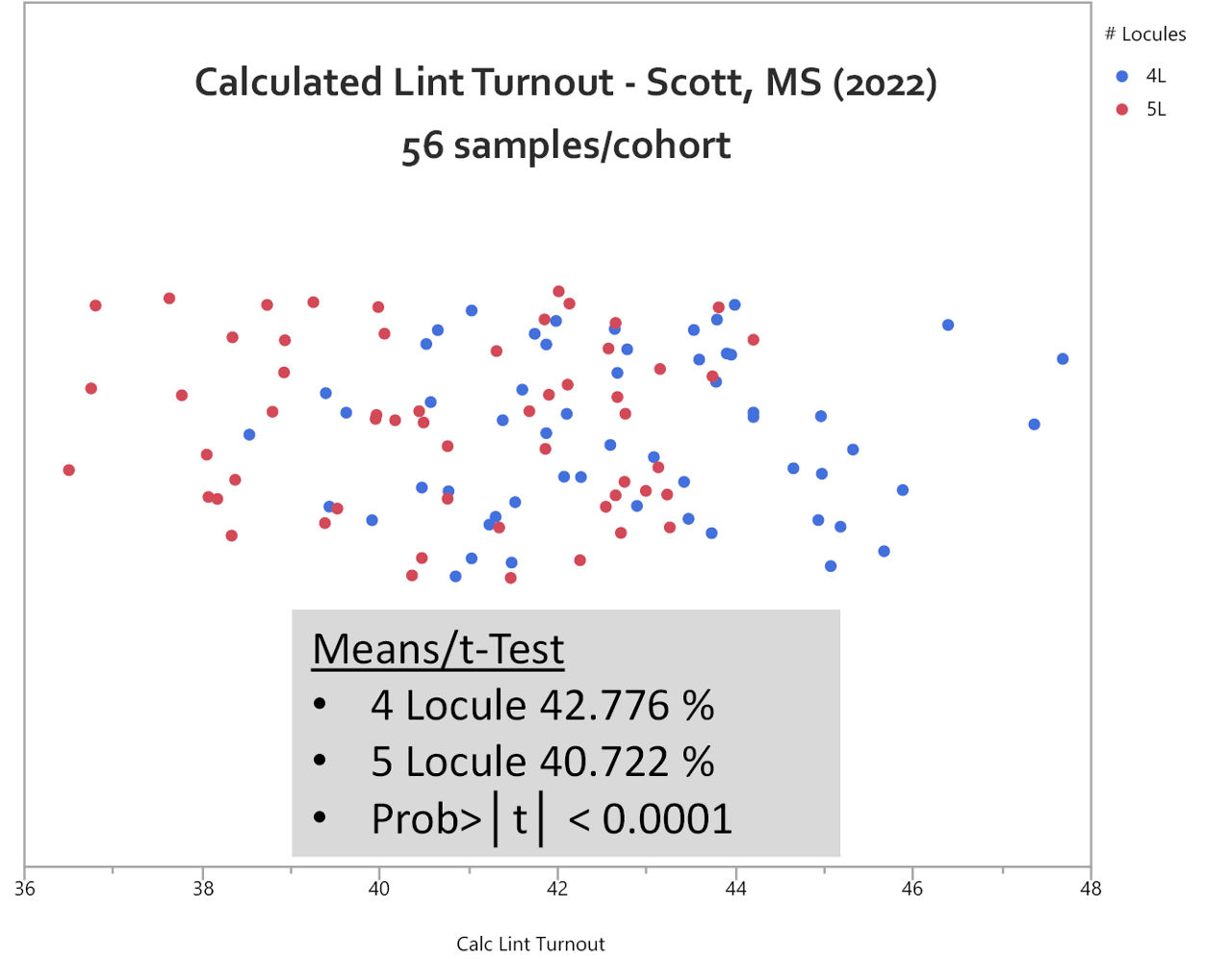

- In the previously discussed row configuration study, the plots were positionally mapped and the bolls were grouped into cohorts of either four- or five-locule containing bolls.

- Four-row feet from each plot, which contained a varying number of plants depending on seeding rate and emergence, was mapped. Data not shown.

- 5,546 bolls were mapped, categorized, delinted, and counted from the plots.

- 4,276 bolls were categorized as four locule (77.1%)

- 1,270 bolls were categorized as five locule (23.9%)

- Bolls were weighed, ginned, tested with High Volume Instrument (HVI) fiber testing, and seeds were delinted and counted.

- Boll size evaluations and data from this step included:

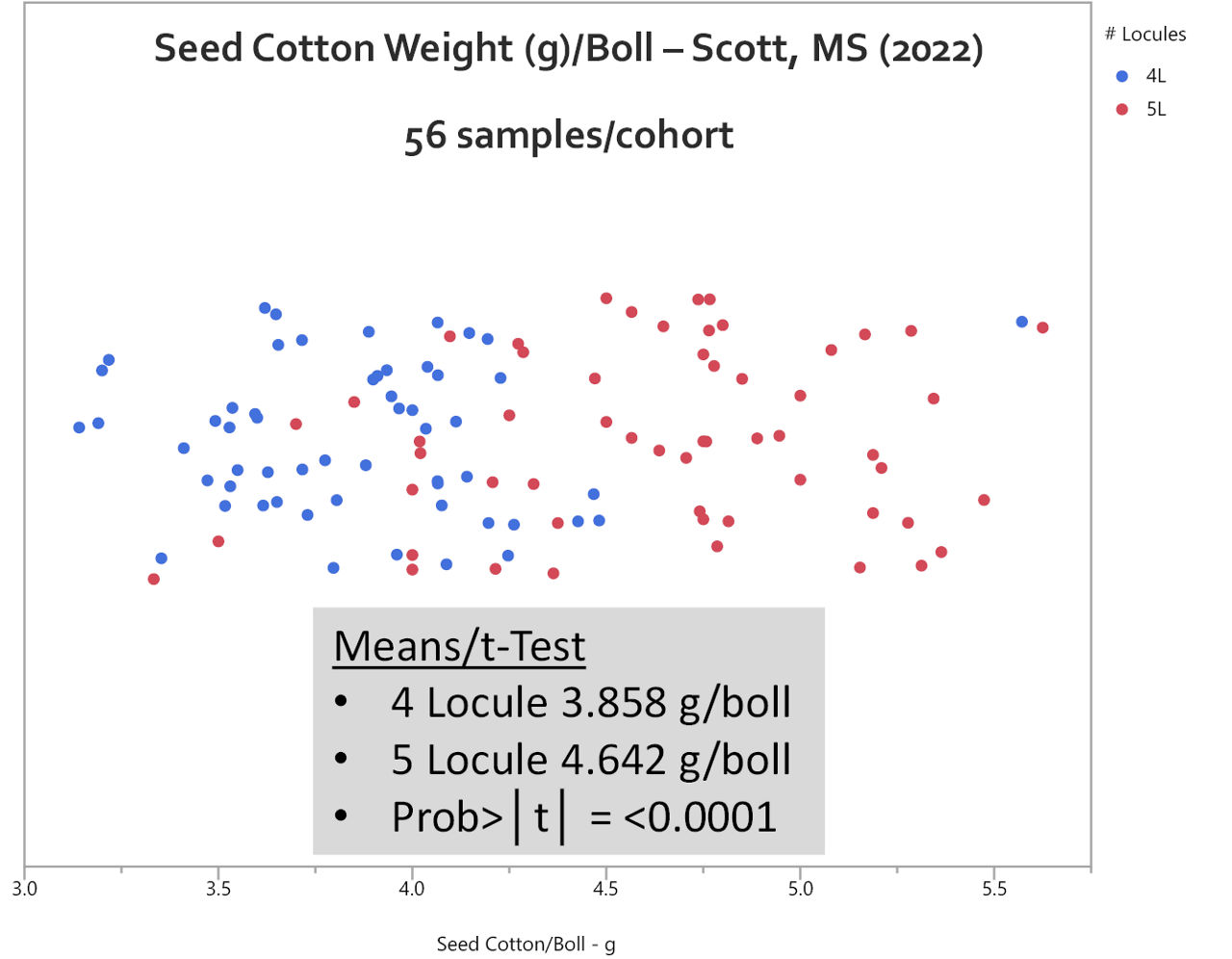

- Seed cotton/boll in grams (significantly more for five locule bolls) (Figure 6).

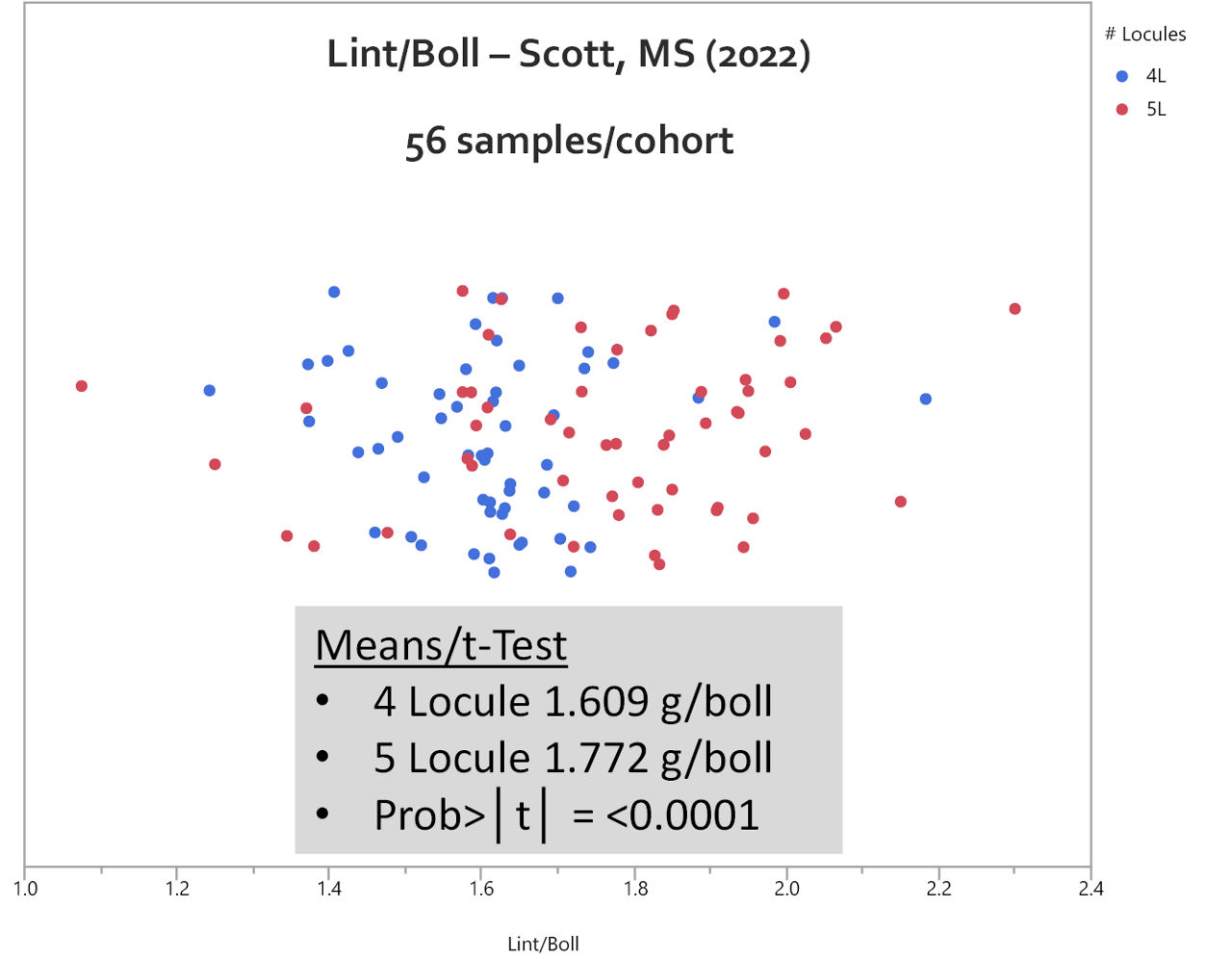

- Lint/boll in grams (significantly more for five locule bolls) (Figure 7).

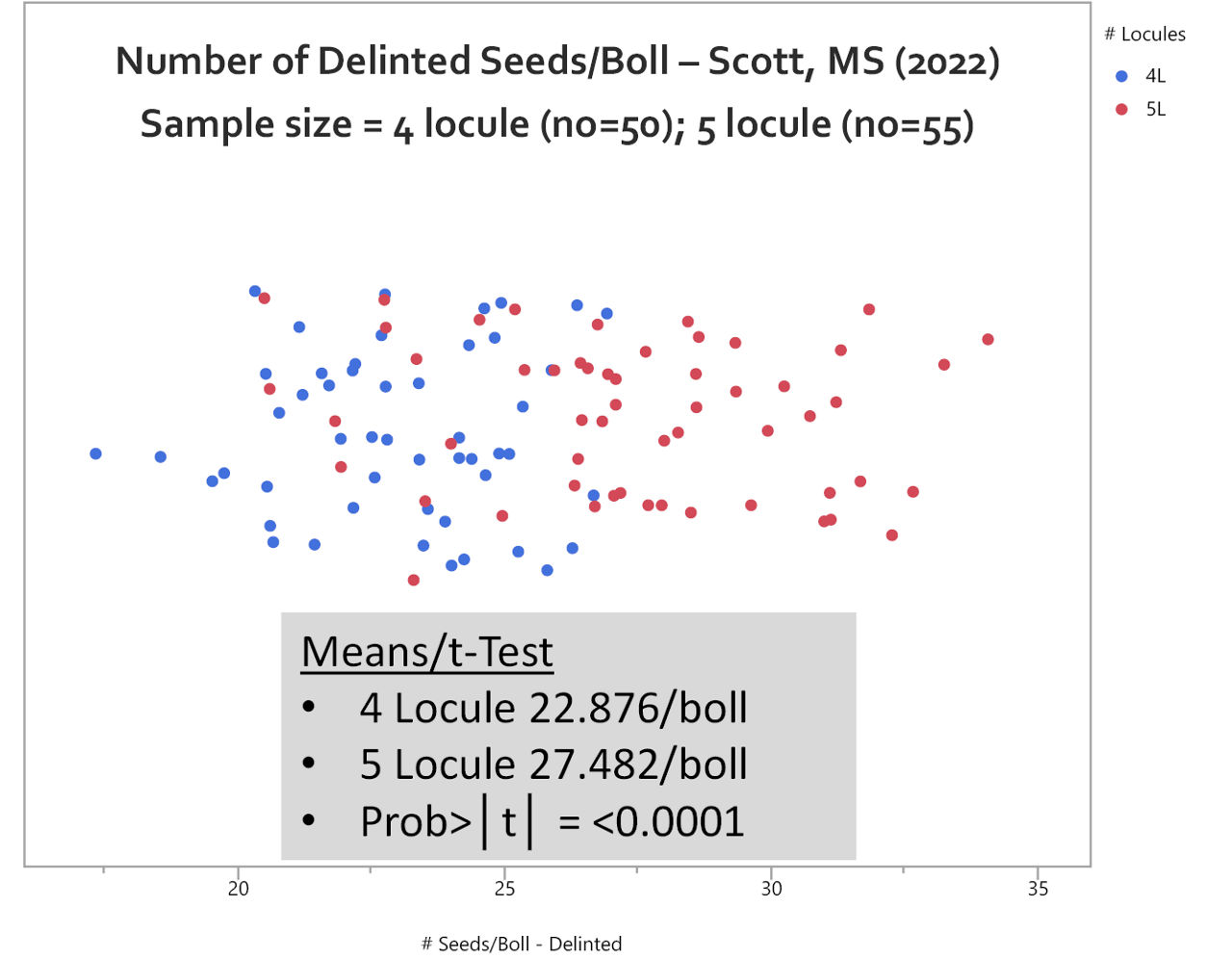

- Number of seed/boll (significantly more for five locule bolls) (Figure 8).

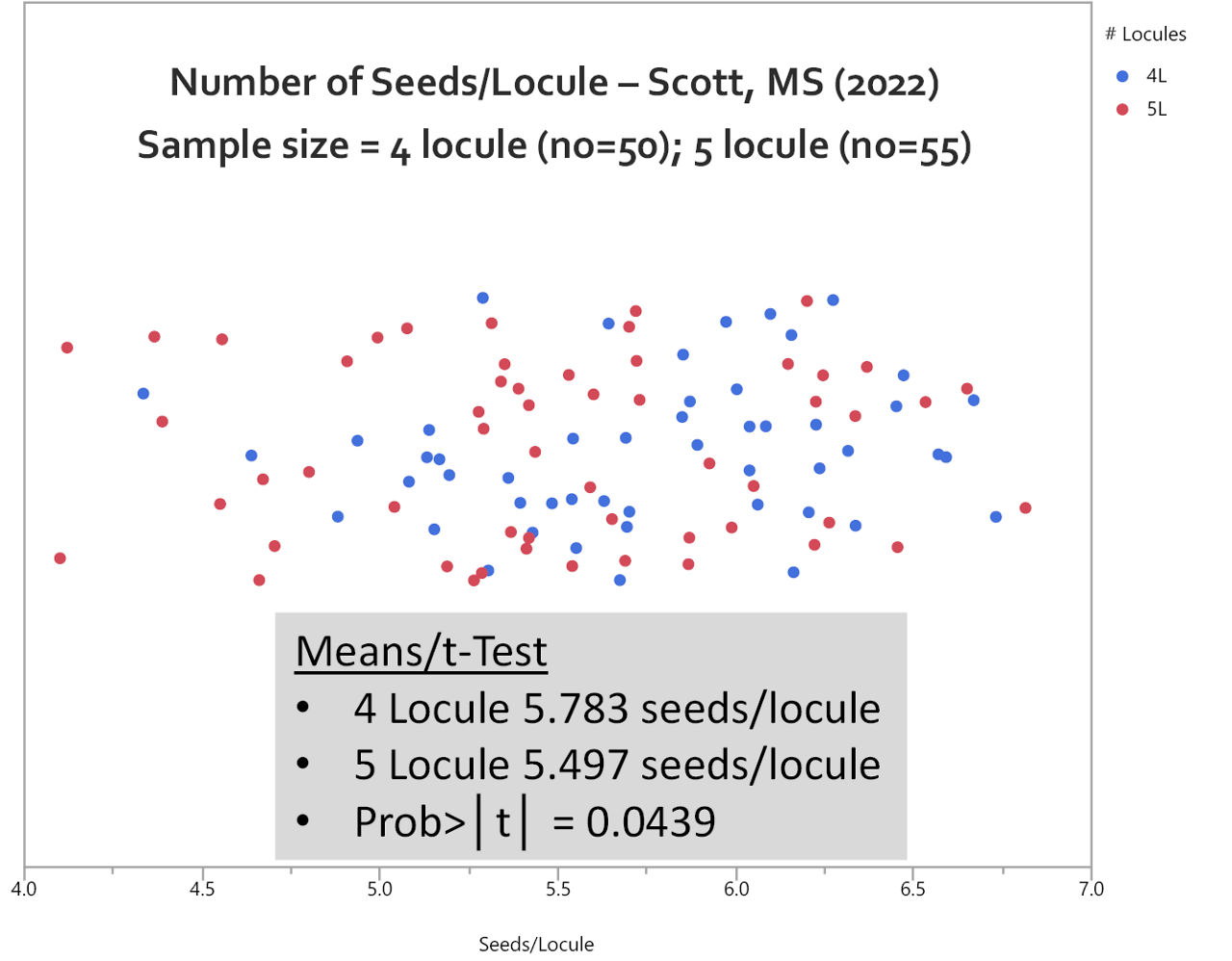

- Number seed/locule (similar for four and five locule bolls) (Figure 9).

- Turnout - % Lint versus seed cotton (similar for four and five locule bolls) (Figure 10).

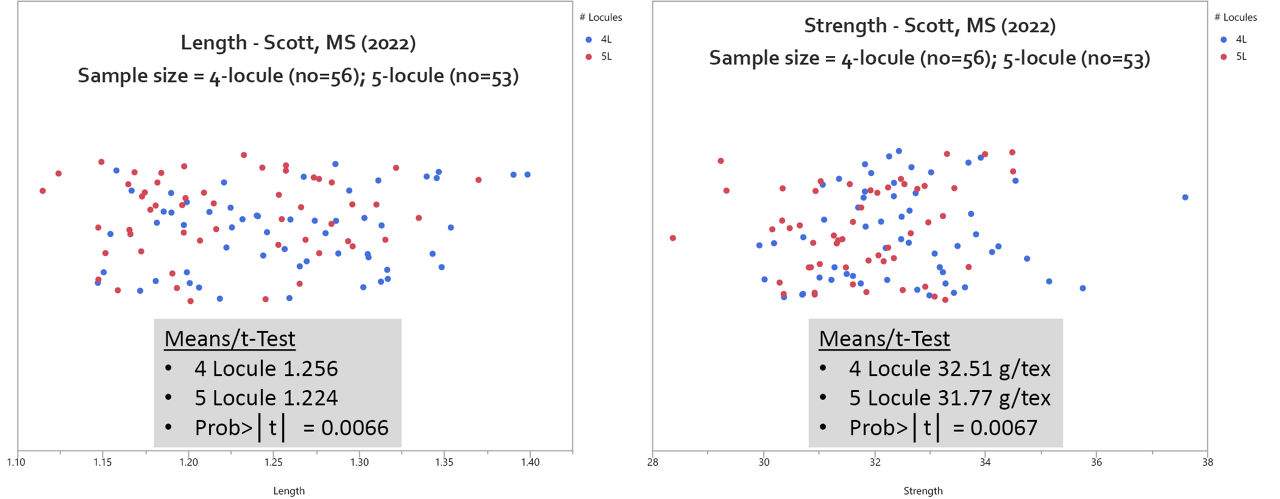

- Fiber quality - Length, strength, micronaire, and uniformity (all similar for four and five locule bolls) (Figures 11 and 12).

- Gross conclusions:

- Five-locule bolls are roughly 10 to 20% larger versus four-locule bolls as measured in seed cotton weight, lint weight, seed number and seed weight.

- The fiber quality of five- and four-locule bolls is similar but did show some minor differences compared to 2021 data.

- Boll size evaluations and data from this step included:

Part II B – Agronomic influences on locule development in cotton.

- Background – Historical (1920’s) and recent literature indicates that locule (4 or 5) determination occurs about 24 to 28 days prior to bloom.1,2 Most cotton bolls in G. hirsutum start with 5 locules and drop to 4 based on carbohydrate status. Typically, less available energy leads to reductions in locule number from 5 to 4. The determination is based mainly on the status of carbohydrate production; higher carbohydrate amounts produced preserve more five locule bolls (Figure 1).

- Factors to consider in carbohydrate availability – All field effects influencing production and availability of carbohydrates should be considered parts of this equation helping to define the relationship including –

- Reduced production – Due to cloudy weather, fertility availability, water logging, drought and other factors.

- Plant to plant competition – This leads to increased vegetative development and tends to make carbohydrates less available, particularly when not managed properly. It is also a primary driver of observed differences among populations.

- Vegetative growth – Any factor that leads to excess vegetative development can reduce carbohydrate availability to the rest of the plant. We manage this using plant growth regulators (PGR) and for that reason PGR use is a factor to consider here since it is primarily used to balance vegetative and reproductive growth.

- Agronomic influences on locule development in cotton:

- Variety

- Variety is a huge component for locule number determination.

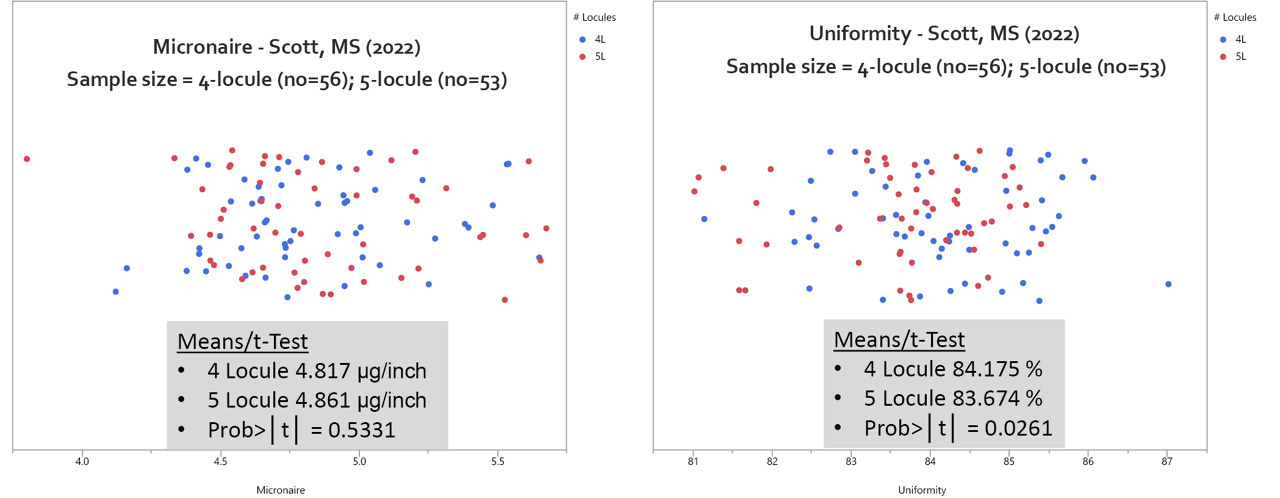

- Some varieties (particularly DP 2038 B3XF in this study) produce more (as much as two times) five locule bolls through various seeding rates (Table 1). This may explain the impact on yield potential and the (mysterious) increase in turnout in some fields.

- The percentage of five locule bolls appears to range from very few (9%) to around 37% depending on the variety, row configuration, and seeding rate combination.

- Table 1 data is averaged across the three row configurations since they were numerically similar.

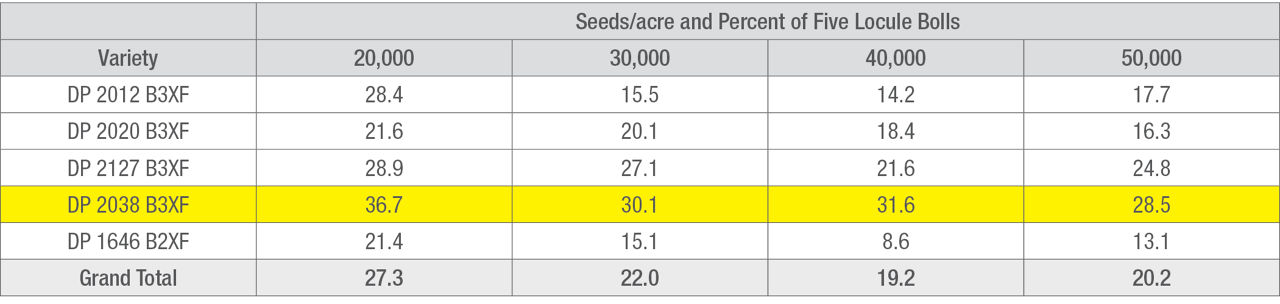

- Averaged across the three row configurations, varieties, and seeding rates in the trial, five locule bolls accounted for 22.2% of the bolls which contributed 25.6% of the harvested dry weight for a yield gain associated to five locule bolls of 3.4% (Table 2).

- This gain can be scaled to the number of five locule bolls contained in each treatment combination to roughly estimate the contribution made to yield.

- Seeding Rate

- Seeding rate effects on locule development appeared similar in all three row configurations but at different magnitudes. In contrast to 2021 all 3 row configurations showed similar trends in five locule boll accumulation. During 2021 the 76-inch 1:1 treatment showed fewer (numerically and as a percentage) five locule bolls. This was not the case during 2022. The data below is averaged across varieties and the three row configurations.

- Less plant-to-plant competition (lower population) can be the trigger for improving carbohydrate availability which could be an influence on the development of five locule bolls.

- Row Configuration

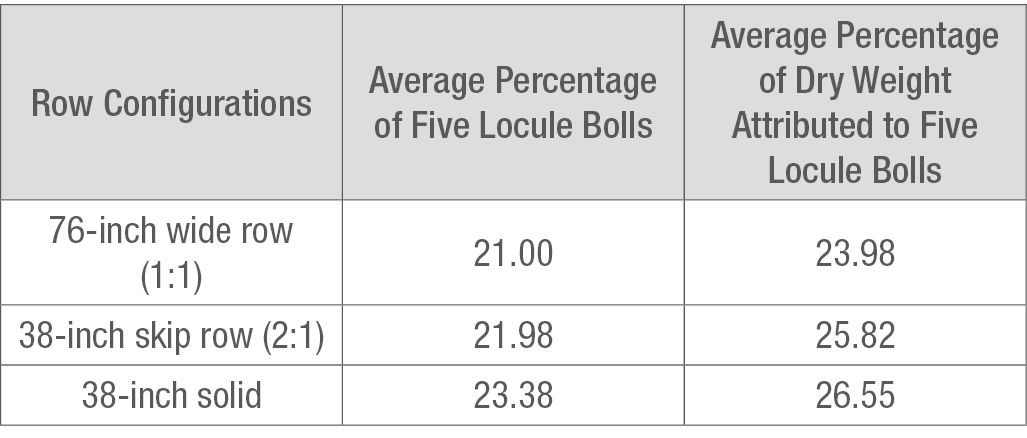

- The data below is averaged across variety and seeding rate within the row configurations.

- All row configurations were similar in the percentage of five locule bolls (Table 3).

- Similar percentage increases of relative dry weight can be attributed to five locule bolls in the three row configurations (Table 3).

- An explanation may be that the average percentage of five locule bolls equals the percentage of the bolls in the treatment combination with five locules. The average percentage of five locule boll weight is the percentage of the dry weight that they contributed to yield.

- Variety

Table 1. Average percent of five locule bolls by variety and seeding rates averaged across all row configurations at Scott, MS (2022).

Table 2. Average percent of five locule bolls for each seeding rate and average percent harvested weight attributed to five locule bolls at Scott, MS (2022).*

Table 3. Average percentage of five locule bolls and average percentage of dry weight attributed to five locule bolls within three row configurations at Scott, MS (2022).

KEY LEARNINGS

- Wider row spacings can produce acceptable yields; however, potential yield may be limited versus solid plantings.

- Growers should carefully consider variety selection and placement when choosing a wide row or skip row configuration.

- Seeding rate management appears to be a useful tool for managing vegetative development in cotton without greatly sacrificing yield potential.

- Five locule bolls, when present, are roughly 20% bigger, have similar fiber qualities, and offer greater contributions to yield potential than four locule bolls when considered on an individual basis; however, all bolls are important and four locule bolls remain the primary contributors to yield potential.

- Agronomic factors that include variety selection, seeding rates, row configuration, drought, irrigation, and other factors influence the development and number of five locule bolls.

- Please see your local Deltapine® brand representative for more information.

Sources:

1Robertson, B., Bednarz, C., and Burmester, C. 2007. Growth and development – first 60 days. Cotton Physiology Today. Vol. 13, No. 2. National Cotton Council. https://www.cotton.org/.

2Oosterhuis, D., Stewart, M., and Guthrie, D. 1994. Cotton fruit development: The boll. Cotton Physiology Today. Vol. 5. No. 7. National Cotton Council. https://www.cotton.org/.

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.