3 MIN READ

Optimum Cotton Planting Conditions and Seed Placement

February 14, 2026

- Careful evaluation of environmental conditions, planter performance, and seeding rate can help establish a vigorous and uniform cotton stand.

- Germinating cotton seedlings are very sensitive to cool temperatures, so planting cotton according to soil temperature and conditions rather than the calendar date helps provide the best possible start to the season.

- A well maintained and calibrated planter increases seeding accuracy, efficiency, and limits delays and headaches in the field.

Soil and Air Temperature Recommendations for Planting Cotton

A simple soil temperature probe can help determine the soil temperature at planting depth. Soil temperatures should be above 65 °F within the germination zone—preferably closer to 85 °F—and soil should be moist prior to planting. Germination may be sporadic if cotton seed is planted into soil temperatures of less than 58 °F.1 Rainfall of one inch or more can drop soil temperatures as much as 5 °F. Imbibition, or the uptake of water through the seed coat, occurs within 24 to 48 hours after planting into moist conditions. Hydration of the seed is critical for germination. However, if the seed is exposed to cooler temperatures, imbibitional chilling injury can occur, damaging the sensitive tip of the taproot or lowering seed viability.

Planting during extended warm air temperatures can help improve germination. Cool air temperatures during the first five days after planting can delay germination, which may lead to reduced stands, increased risk of seedling diseases, and potential yield loss. Avoid planting when air temperatures are forecasted to be below 50 °F during the first five days after the planting date. Cotton requires 50 to 80 DD60s to germinate.1

Soil Condition Considerations for Planting Cotton Seed

Tillage systems can affect how quickly soils warm up in the spring. Soils that have been conservation-tilled, like no-till and strip-till, typically do not warm up as fast as conventionally tilled soils (Figure 1). Increased crop residue can delay the planting date. In no-till production, it is especially important to obtain a good stand on the first try for crop success. Seed should be planted shallow in no-till systems, 0.25 to 0.5 inches deep, making sure the seed furrow is closed. Replanting cotton in no-till systems can complicate weed control and result in an uneven stand.2

Soil warmth may also depend on soil characteristics: texture, color, moisture, and ground cover. Soils that are sandy or that drain well can warm up faster than heavy, water-logged soils. Darker soils and soils that have been bedded up prior to planting tend to warm faster.

Adequate soil moisture and high soil oxygen concentration are favorable for germination and plant growth. Saturated soils, which may include flooded or ponded soils, can inhibit root growth, leaf area expansion, and photosynthesis. Seedlings may fail to emerge, roots may die, and leaves may turn yellow. The longer an area remains saturated, the higher the risk of plant death. In cotton, the radical tip is easily damaged by chilling, lack of oxygen in the soil, or by too much moisture during the first 60 to 100 hours of germination.3 If the root tip is killed, a shallow secondary root system develops that makes the plant more subject to moisture stress later in the season.

Soil crusting occurs when a hard crust layer forms after wet soils dry, causing potential damage to seedlings or decreased emergence. A rotary hoe may be used to carefully loosen the soil surface and should be used as soon as a problem is suspected. Soil crusting is more common in compacted soils with low organic matter. Soil compaction occurs when soil particles are pressed together, decreasing pore space and increasing soil density. Compaction can decrease germination, root and plant growth, and nutrient uptake. Most compaction is the result of equipment passes over a field. Research indicates that approximately 80% of soil compaction happens on the first pass, while subsequent passes cause additional, but progressively less, compaction.4 The best form of compaction management is prevention by staying out of the field until conditions for field work have improved. If mud sticks to the tires and ruts are deeper than an inch, it is too wet to be in the field.

Cotton Planter Preparation

Planter maintenance is important for planter accuracy, planting efficiency, and planter longevity. The following parts should be checked, cleaned, and repaired or replaced if worn: drive trains, sprocket bearings, opener blades, shaft bearings, sprocket teeth, and double disc openers.

Check the down pressure of the closing wheel. Good seed-to-soil contact is essential for quick and even emergence. If soils are dry, increase down pressure to help bring water to the seed. If soils are wet, decrease down pressure to avoid soil compaction around the seed. If there is a vacuum metering system, clean it and check all seals. Calibrate the planter according to the owner’s manual instructions. Follow appropriate planting speeds to help maintain uniform planting.5

Planting depth should be set in the field once soil texture and moisture are determined. Cotton seeds should be planted 0.5 to 1.5 inches deep into adequate moisture.6 Planting too shallow can result in poor seed-to-soil contact and planting too deep can cause stand skips and delayed emergence. Cotton plants require a lot of energy to germinate and planting too deep can burn energy that could be used during root and leaf area development. When dry soils require planting deeper than one inch, plant cotton varieties that are more vigorous, which are typically larger-seeded with greater amounts of stored energy. If soils tend to crust, planting at or close to the 0.5-inch depth is recommended. To determine actual planting depth and spacing, dig up cotton seed behind the planter after planting 50 to 100 feet of row and check depth.

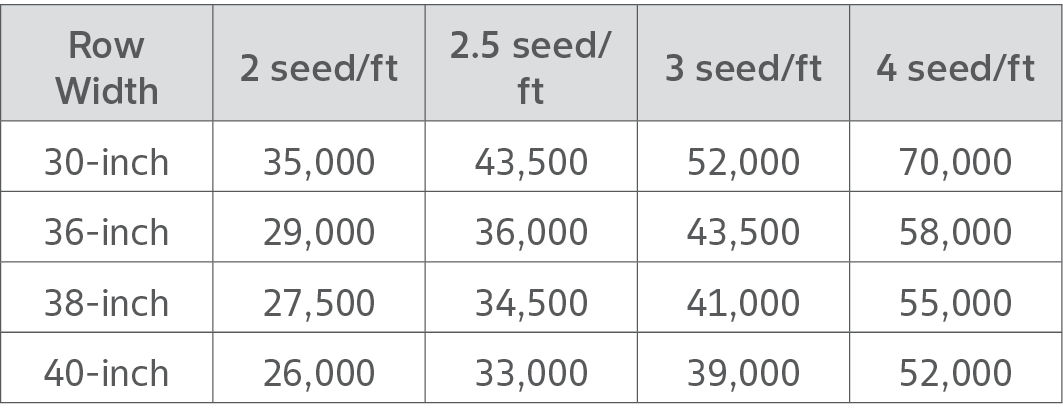

Proper spacing of cotton plants can help maximize yield potential. Planting cotton seed at too high of a seeding rate can cause overcrowding of plants and may unnecessarily increase seed cost. Cotton seed size can vary by variety and the conditions in which it was produced. Recommendations state that final plant population should be determined by the number of seeds per foot of row, and not by pounds of seed per acre. The ideal planting rate may be affected by soil type, water availability, tillage system, and yield expectation. A final stand of 2.5 plants per row foot can typically help maximize yield potential.

Table 1. Cotton seeding rate for desired plants per foot of row.

Sources

12023. A few reminders for planting cotton. University of Georgia Cooperative Extension, Tift County Extension Producer Updates. https://site.extension.uga.edu/tiftcoag/2023/04/a-few-reminders-for-planting-cotton/

2Robertson, B. Tips for no-till cotton production. University of Arkansas Cooperative Extension. AG646-5-02. https://www.uaex.uada.edu/farm-ranch/crops-commercial-horticulture/cotton/Tips%20for%20No-Till%20Cotton%20Production.pdf

3Deterling, D. and El-Zik, K.M. Why getting a stand is so important. Texas Agrilife Extension. How a cotton plant grows. http://cotton.tamu.edu/General%20Production/cotplantgrows.pdf

4Jabro, J., Evans, R., Sainju, U., and Stevens, B. 2025. Impact of soil compaction on soil physical, hydraulic properties and yields. https://www.ars.usda.gov/plains-area/sidney-mt/northern-plains-agricultural-research-laboratory/agricultural-systems-research/asru-docs/soil-compaction/

5Kulkarni, S. Planter preparation, maintenance and calibration. University of Arkansas. FSA1047. https://www.uaex.uada.edu/publications/pdf/FSA-1047.pdf

6Collins, G. and Edmisten, K. 2017. Tips for successful cotton planting: How deep should I plant cotton seed? https://cotton.ces.ncsu.edu/2017/04/tips-for-successful-cotton-planting-collins-edmisten-york-reisig-crozier/

Web sources verified 02/02/26. 1416_105497

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.